2023-05-06

Tag Archives: aluminum gear

China manufacturer Goldgun NMRV aluminum alloy housing speed reducers worm gear gearbox with Good quality

Relevant Industries: Creating Material Shops, Manufacturing Plant, Equipment Mend Retailers, Meals & Beverage Manufacturing facility, Farms, Retail, Foodstuff Store, Printing Stores, Building works , Energy & Mining, Food & Beverage Shops

Gearing Arrangement: Worm

Output Torque: 2-3571N.m

Input Speed: 600-3000rpm

Output Pace: .3-419rpm

Solution name:: GMRV Sequence Worm Pace Reducers

Worm gearbox kind:: GMRV /GRV

Gearbox dimension:: 25.thirty.forty.50.63.75.90.110.130.one hundred fifty

Ratio:: 5,7.5,10,twenty,twenty five,30,forty,fifty,60,eighty,one hundred

Shade:: Blue, Silver or As ask for

relationship variety:: shaft or flange

Input/output shaft:: Strong or hollow

Mounting Situation:: Proper Angle

Certification:: ISO9001

Warranty:: 12 months

Packaging Details: picket circumstances communicate in email-information @ goldgear.cn

Port: ZheJiang

GMRV Series worm pace reducersone.The items composed of worm and worm wheel, 2.with advantages of compact and massive transmission ratio3.It via the IS09001 good quality program certification ,4. The top quality regular Q/MD1 technology layout and producing.5.It is used with modest vibration.6.Mechanical composition is compact,mild condition, 7.tiny volume with substantial effectiveness.8.superior efficiency and effortless routine maintenance.

| 1、Flange PAM | 2、Oli seal | 3、Hexagon socket head cap screw |

| 4、Hexagon nuts | 5、Hexagon bolt | 6、Gear device protect |

| 7、O-ring | 8、Spacer shim | 9、Bearing |

| 10、PAM worm | 11、Double ext. PAM worm | 12、RV worm |

| 13、Double ext. RV worm | 14、Parallel essential | 15、Bearing |

| 16、Washer | 17、Circlip for hole | 18、Cap |

| 19、Oli seal | 20、Case | 21、Plug cock |

| 22、Bearing | 23、Worm wheel | 24、O-ring |

| 25、Bearing help include | 26、Hexagon socket head cap screw | 27、Oli seal |

| 28、Single output Shaft | 29、Double output Shaft | 30、Parallel key |

| 31、Parallel key | 32、Washer | 33、Circlip for shaft |

| 34、Output flange | 35、Hexagon socket head cap screw | 36、Torque arm |

| 37、Hexagon socket head cap screw | 38、Protection cap | 39、Hexagon socket head cap screw |

| 1、 | Worm gearbox type:GMRV= Worm-gear unit with IEC motor interface GRV= Worm velocity reducer with reliable enter shaft |

| 2、 | Gearbox size(Central distance):571, 030, 040, 050, 063, 075, 090,110, one hundred thirty,one hundred fifty |

| 3、 | Reduction ratio:5, 7.5, ten,15, 20, twenty five, thirty, forty, 50, sixty, 80, one hundred |

| 4、 | Double input shaft |

| 5、 | Flange mounting:FA, FB, FC, FD, FE |

| 6、 | Output shaft:ASL, ASR, AB |

| 7、 | Torque arm:T1, T2 |

| 8、 | Input flange(Motor mounting):B5, B14 |

| 9、 | Mounting position:B3, B6, B7, B8, V5,V6 |

| 10、 | Color |

| 11、 | Type:Y2, YD, YVF, Y2EJ…… |

| 12、 | Motor energy |

| 13、 | Poles number:2, 4, 6, 8…… |

| 14、 | Position of terminal box:1, 2, 3, four |

Customer Reviews Software state of affairs Other merchandise Company Profile ZheJiang CZPT M & E Hi- Tech Co.,Ltd. recognized in 2003, is a expert provider engaged in the research, improvement, sale and providers of velocity reducers, motor and transmission components.Our knowledgeable engineers are usually accessible to analysis and examine your needs and make certain total customers’ pleasure. Packing & Shipping Certifications FAQ Q1:Are you a producer or trading company?A1: A business built-in with business and trade.Q2: What about the shipping and delivery methods?A2: For urgent get and gentle bodyweight, you can pick the following categorical: UPS, FedEx, TNT,DHL, EMS. For hefty weight, you can choose to supply the merchandise by air or by sea to conserve cost.Q3: What about the payment approaches?A3: We take T/T, L/C for huge sum, and for small sum, you can spend us by PayPal, Western Union, and and many others.This autumn: How considerably does it price to ship to my nation?A4: It relies upon on seasons. Fee is distinct in distinct seasons. You can check with us at all times.Q5: What’s your shipping and delivery time?A5: Usually we generate in 35-60days following the payment confirmed. If you are urgent, we will urge the production section for you.

Worm Reducer

Worm reducers are commonly used to reduce the Agknx produced by a rotating shaft. They can achieve reduction ratios of five to sixty. In contrast, a single-stage hypoid gear can achieve up to a 120:1 reduction ratio. For further reduction, another type of gearing is used. So, a single stage worm reducer cannot achieve higher ratios than these.<br

Mechanics

A worm reducer is an auxiliary mechanical device that uses worms to reduce the size of a rotating shaft. These worms have a range of tooth forms. One form is a line weave twist surface. Another is a trapezoid based on a central cross section. The trapezoid can be perpendicular to the tooth cross section, or it can be normal to the root cross section. Other forms include involute helicoids and convolute worms, which use a straight line intersecting the involute generating line.

Worm gears are lubricated with a special lubricant. Because worm gears are complex, it’s important to use the correct lubricant. Worm gear manufacturers provide approved lubricants for their gears. Using unapproved gear oil can damage your reducer’s efficiency. The right lubricant depends on several factors, including load, speed, duty cycle, and expected operating temperatures.

The efficiency of a worm gear reducer depends on several factors, including losses at gear mesh, losses in the bearings, and windage in the oil seal lip. In addition, the worm gear reducer’s efficiency varies with ambient temperature and operating temperature. The worm gear reducer’s efficiency can also vary with the ratio of the load. Moreover, worm gear reducers are subject to break-in.

Worm gear reducers are used in many different applications. They are typically used in small electric motors, but they’re also used in conveyor systems, presses, elevators, and mining applications. Worm gears are also commonly found in stringed musical instruments.

Worm gears have excellent reduction ratios and high Agknx multiplication, and they’re often used as speed reducers in low to medium-speed applications. However, the efficiency of worm gear reducers decreases with increasing ratios.

Sizes

Worm reducers come in different sizes and tooth shapes. While the tooth shape of one worm is similar to the other, different worms are designed to carry a different amount of load. For example, a circular arc worm may have a different tooth shape than one with a secondary curve. Worm gears can also be adjusted for backlash. The backlash is the difference between the advancing and receding arc.

There are two sizes of worm reducers available from Agknx Transmission. The SW-1 and SW-5 models offer ratios of 3.5:1 to 60:1 and 5:1 to 100:1 respectively. The size of the worm reducer is determined by the required gear ratio.

Worm gears have different thread counts. One is based on the central cross-section of the worm, and the other is on the right. Worm gears can have either a single or double thread. Single-threaded gears will reduce speed by 50 percent, while double-threaded gears will reduce speed by 25 percent.

Worm gear reducers are lightweight and highly reliable. They can accommodate a variety of NEMA input flanges and hollow output bore sizes. Worm reducers can be found at 6 regional warehouses, with prepaid freight. To make a purchasing decision, you should consider the horsepower and Agknx requirements of your specific application.

Applications

The Worm Reducer market is a global business that is dominated by the North American and European regions. The report provides in-depth information on the market trends, key challenges, and opportunities. It also examines the current state of the industry and projects future market growth. The report is organized into segments based on product type, major geographical regions, and application. It also presents statistics and key data about the market.

Worm gear reducers have many applications. They can be used to increase the speed of convey belts. They also help reduce noise. Worm gears have many teeth that touch the gear mesh, which makes them quieter. Moreover, the worm gears require only a single stage reducer, reducing the number of moving parts in the system.

The worm gear has long life and is suitable for different industries. It is a perfect choice for elevators and other applications that need fast stopping and braking. Its compact size and ability to hold a load make it suitable for these applications. It also prevents the load from free-falling as a result of a sudden braking. Worm gears can also be used in heavy-duty machinery such as rock crushers.

Worm gears are similar to ordinary gears except that they transfer motion at a 90-degree angle. As a result, the worm gears are extremely quiet, making them a suitable option for noise sensitive applications. They are also excellent for low-voltage applications, where the noise is critical.

Worm gears are ideal for applications with space restrictions, because they require fewer gear sets. The worm gears also allow for a smaller gearbox size. Consequently, they are the perfect choice for machines that are space-constrained, such as conveyors and packaging equipment.

Cost

The lifespan of a worm gear reducer is comparable to other gear reducers. Worm gears have a long history of innovation and use in various industries, from shipbuilding to automobile manufacturing. Today, these gear reducers are still popular with engineers. However, there are some things to keep in mind before buying one.

In the first place, a worm reducer needs to be affordable. Generally, a worm reducer costs about $120. The price varies with the brand name and features. Some products are more expensive than others, so be sure to shop around for the best price. In addition, it is important to consider the quality and design of the worm reducer before making a purchase.

Worm gear manufacturers have made significant advancements in materials, design and manufacturing. These advancements, along with the use of advanced lubricants, have resulted in significant increases in efficiency. For example, double enveloping worm gear reducers have improved efficiency by three to eight percentage points. This improvement was achieved through rigorous testing of manufacturing processes and materials. With these improvements, worm gear reducers have become more desirable in today’s market.

Worm reducers are extremely versatile and reliable, and are available in a variety of sizes. Domestic manufacturers usually stock a large selection of reducers, and are often able to ship them the same day you place your order. Most major domestic worm gear reducer manufacturers also share some critical mounting dimensions, such as the output shaft diameter, the mounting hole location, and the overall reducer housing height. Most manufacturers also offer standardized gear ratios. Some manufacturers have also improved gear design and added synthetic lubricants for better performance.

In addition, different tooth shapes of worms can increase their load carrying capacity. They can be used on secondary curves and circular arc cross sections. Moreover, the pitch point defines the boundary of the cross section. The mesh on the receding arc is smoother than that of the advancing arc. However, in the case of negative shifting, most of the mesh is on the receding arc.

Self-locking function

A worm reducer has a self-locking function. When a worm is fitted with all of its addendum teeth, the total number of teeth in the system should be greater than 40. This self-locking function is achieved through the worm’s rack and pinion mechanism. The worm’s self-locking feature can prevent the load from being dropped and is useful for many applications.

The self-locking function of a worm reducer is possible for two main reasons. First of all, a worm reducer uses two or more gears. One gear is placed at the input, and the other gear runs the output shaft. This mechanism produces a torque, which is transmitted to a spur gear.

Worm reducers can be used in a variety of industrial applications. Because of their self-locking function, they are useful for preventing back-driving. They are also helpful for lifting and holding loads. Their self-locking mechanism allows for a large gear reduction ratio without increasing the size of a gear box.

Self-locking gears can be used to prevent back-driving and inertial driving. This is useful for many industries and can prevent backdriving. However, one major disadvantage of self-locking gears is their sensitivity to operating conditions. Lubrication, vibration, and misalignment can affect their reliability.

Embodiments of the invention provide a self-locking mechanism that prevents back-driving but allows forward-driving. The self-locking mechanism may comprise first and second ratchet cams disposed about a gear member. A releasable coupling member may be interposed between the gear member and the ratchet cam. This facilitates selective coupling and decoupling.

The worm reducer has several advantages. Its compact design is ideal for many mechanical transmission systems. It also provides greater load capacity than a cross-axis helical gear mechanism.

in Bremen Germany sales price shop near me near me shop factory supplier Bevel Gear Plastic Stainless Steel Aluminum Zinc Motor Wheel Diameter Shafts Pin Nylon Bore Straight Spiral Tooth Brass Shaft Adjustabletable High Quality Gears manufacturer best Cost Custom Cheap wholesaler

Our firm pays particular consideration to customers’ wants, listening to the certain requirements of every single client and guaranteeing total pleasure. EPG will often adhere to it business spirit of becoming sensible, progressive, productive and outstanding to make the best intercontinental transmission push. we have received the trust of purchasers around the world.

EPTl Gear Plastic Stainless Steel EPT Zinc EPT Wheel Diameter Shafts Pin Nylon Bore straigEPT spiral Tooth Brass Shaft Adjustabletable Higher EPT Gears

EPTl Gears arrive in pairs, with equally EPTs obtaining differing numbers of teeth. They can have straigEPT or spiral (curved indirect) teeth, but alwaEPTfeature a conical shaped, pitched surface. EPTl Gears can have outward ( exterior ) or inward ( internal ) facing tooth. As EPTl Equipment pairs are in no way similar they are supplied in matched remaining and appropriate-handed pairs.

EPTl EPTs are these that use two conical toothed wheels to transfer EPT in between axes that are reduce inside of the identical room nevertheless, hypoid EPTs can transfer EPT between two axes that cross each other.

Tooth of a EPTl EPT can be either straigEPT or spiraled, which is also acknowledged as a conical helix. Distinct sorts of EPTs can be classified based mostly on their tooth width, but also on the tooth face width or the cEPTr’s circular pitch

Best China manufacturer & factory factory manufacturer for agricultural machinery transmission aluminum alloy steel gear and shaft cnc machining part With high quality best price

Our technicians and engineers have 23 years of Experience in the Bearing Industry.

Overview

Quick Details

- EPG is willing to cooperate sincerely and develop commonly with friends! Applicable Industries:

-

Manufacturing Plant

- Application:

-

Industrial Equipment

- Size:

-

Customized Size

- Surface treatment:

-

Plating

- Tolerance:

-

0.01-0.05mm

- Certification:

-

ISO9001:2008/TS16949

- Service:

-

Customized OEM

Supply Ability

- Supply Ability:

- 10000 Piece/Pieces per Month

It must be fixed on a flat surface to avoid either vibrations or tensions nonwished

Packaging & Delivery

- Packaging Details

- Neutral paper packaging, wooden boxes for outer box or according to customer’s demand

- Port

- Shanghai Port or Ningbo Port

-

Lead Time

: -

Quantity(Pieces) 1 – 1000 >1000 Est. Time(days) 15 To be negotiated

Online Customization

Single direction FREE WHEEL (RA) Single direction PAWL torque limiter (SW) Disc torque limiter clutch with spring (FFT)

We Ever-Power Group with 4 branches over 1200 workers is one of the biggest transmission parts and machining items manufacturers in China

Product Description

agricultural machinery transmission aluminum alloy steel gear and shaft cnc machining part

We specialized in manufacturing automobile gears , motorcycle gears, gearbox, special vehicle (power takeoff, snowmobiles, engineering vehicles) gears, generator accessories, stainless steel ice crusher etc.

|

Material |

1020,1045,20CrMnTi, etc. |

|

Machining Process |

Gear Hobbing , Gear Shaping, Gear Shaving, Gear Grinding |

|

Modules |

1.0, 1.25, 1.5, 1.75, 2.0, 2.25, 2.5….8.0 etc. |

|

Heat Treatment |

Carburizing & Quenching, Carbonitriding |

|

Standard |

DIN, ISO/GB, AGMA, JIS,ISO/TS16949:2009 |

Packaging & Shipping

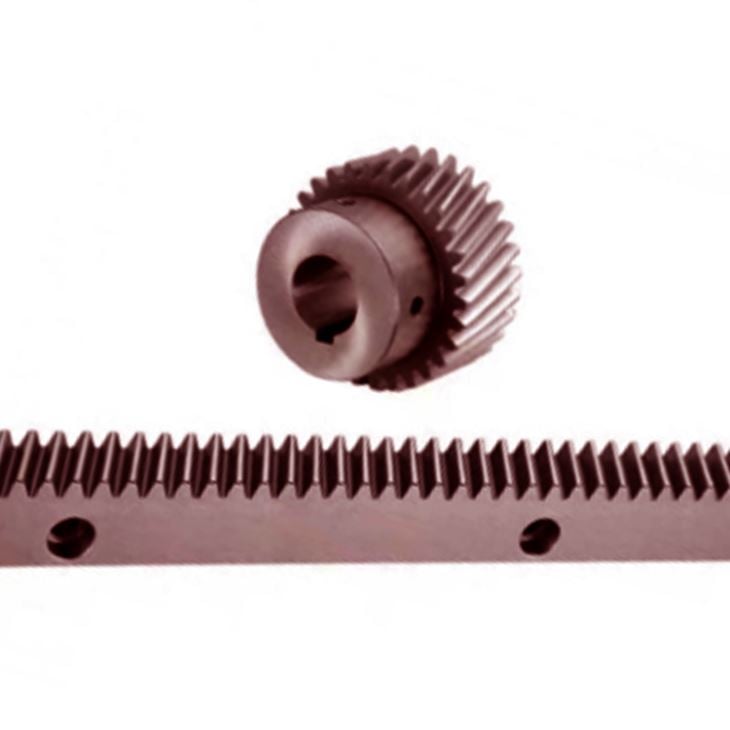

Customized China aluminum gear rack and pinion made by Junhong gear rack factory – Supplier Manufacturer wholesaler Factory

For more details.: Cell/Whatpp: +8613083988828

When the PTO has begun to power the attachment, steadily enhance the throttle till you reach the operating pace. The normal running RPM (revolutions per moment) for a tractor mounted PTO is 540 RPM, though there are tractor models that rev larger. Always refer to your certain tractor design for recommendations prior to first-time use.We have built a large infrastructural unit equipped with progressive technology devices for making an unparalleled range of products, which are in compliance with the industry specifications and the common marketplace tendencies. Each and every procedure, every single part, each perform in EPG is demanded to be completed one stage adhering to another, carefully and cautiously, from materials selection, reformation to production components, from elements warmth therapy to automated assembly, from quality control to item inspection and screening and from get working to soon after product sales services.”EPG” model rotocultivator ploughshares in T.S. complete lines created in our manufacturing facility have been tested and appraised by the Ministry of Agriculture and have attained the license of popularizing farm machinery promulgated by the Ministry of Agriculture of the People’s Republic of China.

Overview

Swift Information

- Relevant Industries:

-

Production Plant

- Colour:

-

Aluminum shade

- Surface:

-

With groove hole

- Duration:

-

Customized

- Heat treatment:

-

No

- Module:

-

.4-eight

- Provider:

-

Reply in twelve several hours at any time

- Packing:

-

Oil+PE bag+ Wooden scenario

- Teeth Sort:

-

Spur teeth or Helical tooth

- Other substance:

-

Steel, Brass, Nylon, POM and so on.

Provide Capacity

- Provide Capability:

- 5000 Piece/Parts for every Month

Packaging & Shipping and delivery

- Packaging Specifics

- Antirust oil + PE bag + Wood scenario

- Port

- Ningbo, Shanghai or as ask for

-

Lead Time

: -

Quantity(Luggage) 1 – two hundred 201 – five hundred 501 – 2000 >2000 Est. Time(times) twenty 30 45 To be negotiated

On the internet Customization

Tailored aluminum equipment rack and pinion made by Junhong gear rack manufacturing unit

Solution description

Our spur and helical gear racks are welcomed by several consumers for its steady high top quality and aggressive price.

The producing character of JH gear racks.

one. Gear rack duration: the longest is 4000mm with no joint. It can be jointed to any duration.

2. Material: steel C45, stainless steel, large power steel, copper, aluminium, nylon, plastic, POM and so forth

3. Module: .three-eight (pitch from .942-25.12mm, DP 3.one hundred seventy five-eighty five)

4. Surface: zinc (galvanized), black, chromium plating, nickel plating, quenching and tempering and many others.

five. Quality: steady and substantial: amassed tolerance .1mm for each 1000mm for normal high quality

Accumulated tolerance .02mm for every 1000mm for four sides floor.

Rates for previously mentioned high quality are very aggressive for us.

six. Heat remedy: tooth can be hardened to HRC 43-50.

The top quality character of JH equipment racks:

1. Stable transmission and low sounds

2. Effectively stay away from normal tolerance primarily based on substantial precision

three. The surfaces can be ground to quality 7 good quality, and enamel can be floor to quality 6 good quality

4. The mounting holes can be produced as request

5. The cost is aggressive even the quality is large.

| Amenities |

Machining center CNC equipment hobbing equipment CNC equipment shaper CNC gear grinding device CNC turning machine CNC milling machine. Y58200 CNC huge gear rack shaper, Y58125A equipment rack shaper, England equipment rack shaper and Russia gear rack shaper, Gleason machine. |

| Substance |

Steel: C45, Q235, 40Cr, 20CrMnTi, and many others. Stainless steel: 301, 201, 304, 316 and so on. Brass: H59 H68 H80 H90 and so on. Aluminium: 6082, 6061, A380 etc. Aluminium alloy: 6061, 5083, 7050, etc. Much more: PA6, PA66, POM, Ab muscles and many others. |

| Enamel kind |

Spur teeth equipment rack Helical enamel gear rack Round gear rack Tube gear rack Curved gear rack. |

| Surface area | Polishing Plating Galvanized Black chromium plating, nickel plating painting and many others. |

Actual photos

Our Companies

1. Supply time: 15-25 days for small buy

30-forty five days for massive buy. (Never delayed until now)

Can be mentioned for a lot more urgent order.

2. Reaction time: usually in 1 hour and in 12 hours even in our vacations.

3. Process opinions: Photos or vedios will be despatched for 2-three moments to inform you the generating situation.

4. Take a look at report: The check report can be supplied as ask for.

5. Payment terms: T/T, L/C, D/P, D/A, O/A, M/T, D/D and so forth.

6. Trade phrases: FOB, CFR, CIF, FCA, CPT, CIP, DDU, DDP and many others.

Organization Data

FAQ

Q: Company?

A: Of course. Given that 2004 only emphasis on making high top quality gears and racks.

Q: Response time?

A: Reply very quickly, and reply in 12 hrs at any time.

Our technicians are usually together with salesmen, so your any inquiries can be replied quite before long.

Q: Price tag?

A: Drawings are much more appriated for quotation. Or, you should inform us your ask for, we will make drawings for your check.

Q: Shipping time?

A: 15-25 times for little order (<200 pcs), 30-45 days for large order.

Orders by no means be delayed, the goods will be despatched on time as agreement.

Q: Good quality?

A: Center and large top quality is much more aggressive.

Q: Payment conditions?

A: T/T for less than US$twenty,000 purchase, and L/C, D/P, D/A, O/A, M/T, D/D and many others. for large orders.

Q: Trade conditions?

A: FOB, CFR, CIF, FCA, CPT, CIP, DDU, DDP and so on. are all recognized.

Sizzling relevant goods

Speak to us

EPG – one of the most significant transmission manufacturing unit in China, main merchandise: worm geared motors, agricultrual gearbox, planetary equipment drive, helical,screw, beve gears and spare components and agricultural parts manunfacuter in China /For more data.: Cell/Whatpp: +8613083988828

EPT China High Quality Aluminum RV Type Worm Gear Boxes – Supplier Manufacturer wholesaler Factory

For a lot more info.: Cellular/Whatpp: +8613083988828

It has recognized stable cooperation with a lot of well acknowledged universities and institutes in china this kind of as, Zhejiang College, Jilin College, Technological committee of national chain drive standard, Institute of countrywide chain generate, Zhejiang software engineering materials institute, Huhan materials security institute and it cooperated to located China Very first Car chain institute with Countrywide chain generate institute.The organization masking 88,000 sq. meters, has advanced gear and sturdy technical strength, this sort of as the numerical handle equipment resources and machining centers, CAD/CAM method, industrial robotic and many others.

Overview

Rapid Particulars

- Relevant Industries:

-

Developing Content Shops, Production Plant, Equipment Repair Retailers

- Gearing Arrangement:

-

Worm

- Output Torque:

-

two.6-1195N.m

- Input Pace:

-

1400r/min

- Output Pace:

-

23.three-186.7r/min

- Area of Origin:Zhejiang, China

- Brand name Identify:

-

OEM

- Product Number:

-

NMRV

- Rated Electrical power:

-

.06-15KW

- Product Name:

-

Aluminum RV Type Worm Equipment Containers

- Frame Material:

-

Aluminium Alloy or Solid Iron Housing

- Worm Shaft Substance:

-

Carburizing Metal, 20CrMnTi, fifty eight-62HRC

- Worm Wheel:

-

Bronze Alloy

- Bearing Brand name:

-

NSK, C&U

- Lubricant:

-

Artificial or Mineral Lubrication Oil

- Certification:

-

CE ISO9001

- Warranty:

-

twelve Months

Offer Capability

- Offer Capacity:

- 600000 Piece/Parts per Month

Packaging & Shipping and delivery

- Packaging Details

- Standard export packing and wooden pallets packing

- Port

- Shanghai or Ningbo Port

On the internet Customization

Item Description

Aluminum RV Type Worm Gear Containers, mounting dimensions can interchangeable with MOTOVARIO.

one. Created of substantial-quality aluminium alloy, mild bodyweight and non-rusting

two. Large output torque

three. Clean managing and lower sound

4. Large radiating effectiveness

five. Excellent-looking visual appeal, sturdy services daily life and small quantity

6. Suitable for omni-bearing set up.

In depth Photographs

Comprehensive Photographs of Aluminum RV Kind Worm Gear Packing containers

Packing & Shipping

Packing Pictures of Aluminum RV Kind Worm Equipment Containers

Inner Packing: PP bag with carton

Outer Packing: Wood scenario

Shipment: fourteen-twenty times upon obtaining the deposit.

About Us

At any time_electricity Group is the first and greatest worm gearbox company in China, set up in 1976, specialising in the creation of a broad selection of transmission equipment. With much more than 40 many years knowledge in the sector, our belongings now whole 117.2 million dollars, and we have two subsidiary firms, eight keeping firms, and twelve joint-stock organizations.

We can produce four hundred,000 models of worm gearboxes, a hundred,000 units of gear gearboxes, fifty,000 models of other speed gearboxes, a hundred and fifty,000 models of flexible couplings, and a hundred,000 units of speed-gearbox add-ons every single year.

70% of our items have been exported to 40 more international locations, and our consumers occur from Italy, Germany, United states of america, Canada, Spain, Uk, India, Mexico, Brazil, Argentina, Turkey, Singapore and other major industrial nations. thirty% of them are OEM made for immediate manufacturers of other products.

FAQ

Q1. Is your quality excellent?

A1: High quality in no way tell lies, we’re the greatest producer and exporter of worm equipment gearbox in Asia, the first gearboxes and gearboxes producer in China, who has been presented license because 1993. Also, we had achieved ISO9001 and CE Certification between all manufacturers.

Q2. How is your price tag? Can you supply any price reduction?

A2: We will give the best price tag we can base on your requirements and the portions.

Q3. Do you offer you any visiting?

A3: Of course! We sincerely invite you to check out us! We can decide you from airport, railway station and so on. Also, we can prepare housing for you. Remember to enable us know in superior.

Q4. When is the greatest time to make contact with you?

A4: You can make contact with us by electronic mail any time, we will reply you ASAP. If you want make contact with by phone, our functioning hour is Mon-Sat 9am-seventeen:30pm.

Speak to

Ever_electricity Group

Handle: No.789-B8Shenhua Street, XiHu Dsitriction Enco&Tech Advancement Zone HangZhou Town, ZJ, P.R.

Tel: 0086-571-88220971/Mob: +86 13083988828

WhatsApp/Skype: +86 13083988828

Web site: www.hzpt.com

EPG – 1 of the biggest transmission factory in China, major goods: worm geared motors, agricultrual gearbox, planetary equipment generate, helical,screw, beve gears and spare components and agricultural components manunfacuter in ChinaFor far more info.: Mobile/Whatpp: +8613083988828